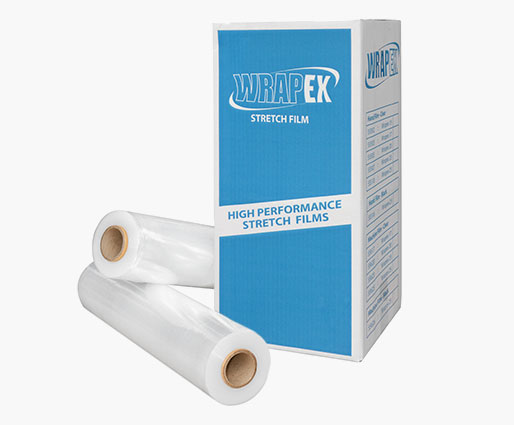

A guide to shipping your products safely & efficiently using Wrapex® High Performance Stretch Films

Date Posted:6 August 2024

Shipping pallets safely and efficiently to your customer can be difficult, as so many factors weigh into the process. Ensuring your products are wrapped securely with high quality stretch film can prevent product damage during transportation and minimise customer claims. Pallets that are wrapped correctly can also discourage load tampering and reduce the risk of injury to workers.

Wrapex® range of Premium Stretch Films are thin but strong. These high yield, high performance multi-layered films are manufactured using a cast extrusion process from a special blend of materials. Compared to most other stretch films on the market, Wrapex® premium pallet wrapping stretch films require less force to stretch, have increased tear resistance, low noise application and offer a superior double sided cling.

ADVANTAGES OF WRAPEX® STRETCH FILM

Wrapex® stretch films are clean and easy to use, they provide excellent cling without leaving any sticky residues on your products. They have excellent clarity - stock is easily identified through the transparent film, which permits quick and accurate barcode scanning through the film. Wrapex® stretch films have excellent membrane memory: pallets stay safe and tight during transport. Wrapex® premium stretch films are available in both hand and machine rolls.

|

|

|

|

|

|

Wrapex® stretch films are made from 100% recyclable plastic, accepted everywhere that recycles soft plastics. Wrapex® films also offer high stretch and yield: reducing the amount of stretch wrap required to wrap each pallet, and resulting in less waste and reduced environmental impact.

WHICH STRETCH FILM SHOULD I USE?

With so many options available, the process of selecting the appropriate stretch film can be daunting and confusing. Below is some information to help you decide which film will suit your needs best.

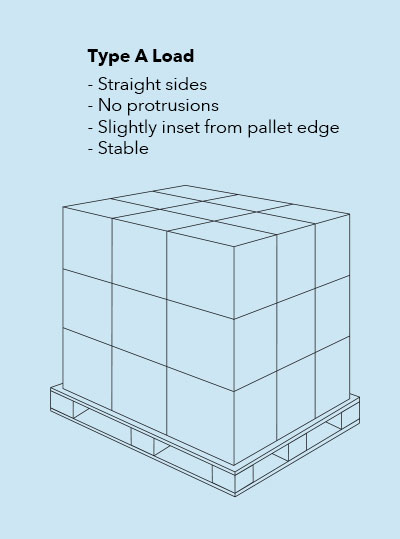

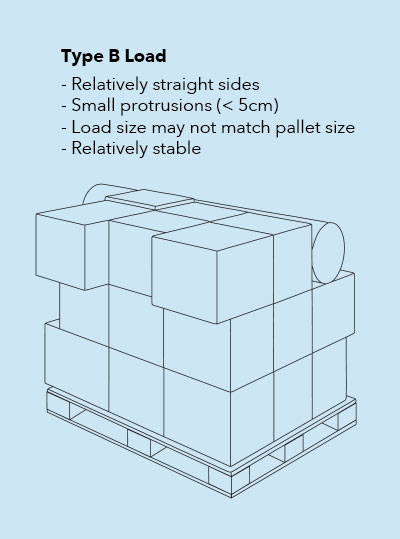

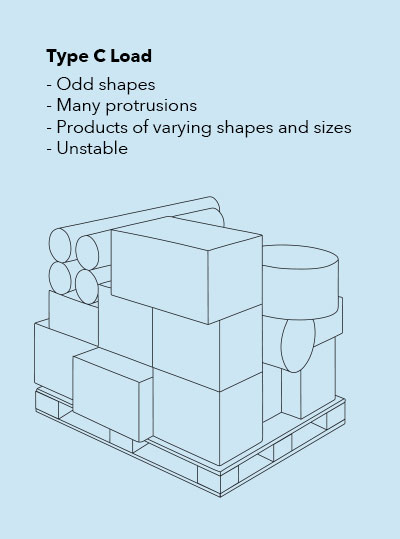

The first thing you need to consider is what type of load you will be wrapping. Stretch wrap and pallet machine manufacturers have divided the types of pallet loads into three main categories. This is based on the load stability, difficulty of wrapping and amount of protrusions.

- Type A Loads are uniform in shape and have no protrusions. These loads have few potential wrap puncture points. This style of pallet load most often only includes a single product, or multiple products that have identical packaging. Depending on the weight of the pallet load, this style of pallet load can generally be wrapped using a thinner gauge film.

- Type B Loads may contain irregularly shaped products, or the load size may not match the pallet size causing several wrap puncture points to exist. These loads usually contain two or three different shaped products destined for a single destination. Generally, this type of pallet load can be wrapped using a mid-gauge stretch film.

- Type C Loads consist of many different products of varying shapes and sizes. These are the most difficult to wrap because no two loads are the same. This type of pallet load often has many potential puncture points and requires a stronger film with high puncture resistance.

|

|

|

Once you know what type of load you will be wrapping, you'll be able to select the appropriate hand or machine stretch film, depending on whether you’ll be wrapping your pallets by hand or machine. The below guide to help you decide which film will best suit your needs.

WRAPEX® HAND FILMS

|

|

|

THICKNESS (microns) |

PRODUCT CODE |

SIZE |

USAGE |

|---|---|---|---|

|

12µm |

500mm x 550m |

Excellent for Type A pallet loads up to 400kg. |

|

|

15µm |

500mm x 450m |

A great option for Type A pallet loads up to 600kg. |

|

|

17µm |

500mm x 350m |

Ideal for Type A pallet loads up to approx. 800kg. |

|

|

20µm |

500mm x 450m |

A versatile option, with higher puncture resistance than lower gauge films. Great for Type A or B pallet loads up to 1 tonne (1000kg). |

|

|

23µm |

500mm x 400m |

Strong film with high puncture resistance, ideal for taller, less stable and heavier pallet loads of up to 1.1 tonnes (1100kg). Suitable for Type A, B and C load types. |

|

|

25µm |

500mm x 400m |

Our thickest film gauge, suitable for Type A, B and C pallet loads of up to approx. 1.3 tonnes (1300kg). This film offers high strength and puncture resistance, however requires maximum exertion during hand application. |

WRAPEX® MACHINE ROLLS

|

|

|

THICKNESS (microns) |

PRODUCT CODE |

SIZE |

USAGE |

|---|---|---|---|

|

17µm |

500mm x 1920m |

Ideal for Type A pallet loads up to approx. 800kg. |

|

|

20µm |

500mm x 1630m |

A versatile option, with higher puncture resistance than lower gauge films. Great for Type A or B pallet loads up to 1 tonne (1000 kg). |

|

|

23µm |

500mm x 1420m |

Strong film with high puncture resistance, ideal for taller, less stable and heavier pallet loads of up to 1.1 tonnes (1100 kg). Suitable for Type A, B and C load types. |

|

|

25µm |

500mm x 1305m |

Our thickest film gauge, suitable for Type A, B and C pallet loads of up to approx. 1.3 tonnes (1300kg). This film offers high strength and puncture resistance, and is most effective using machine application. |

WRAPEX® BUNDLING FILM

|

|

|

THICKNESS (microns) |

PRODUCT CODE |

SIZE |

USAGE |

|---|---|---|---|

|

20µm |

100mm x 300m |

This narrow width film is excellent for wrapping or “bundling” small irregular shaped products. |

OTHER OPTIONS

Opaque Black Stretch Film

Wrapping your pallets in opaque black stretch film offers a variety of advantages over clear stretch film. A few advantages include:

- Conceals valuable goods to deter theft - If your pallet loads are a high dollar value and travel long distances outside your companies care, black stretch wrap is a great solution. Stretch film is a tamper evident product so you can tell if the pallet load has been broken into.

- Helps to protect products from UV Rays, prevents fading and outlasts clear stretch film during extended outdoor storage.

|

|

Wrapex® Opaque Black Stretch Film is available in the following options:

Ventilated Stretch Film

Ventilated stretch film is perforated with holes that allows air to flow in and around your wrapped products. Ideal for products that are likely to get damaged by humidity or condensation, as well as products that need to chill or freeze quickly. A stronger alternative to Stretch Pallet Netting.

- Breathability during transport dramatically reduces moisture-related spoilage.

- Products requiring refrigeration and freezing cool down and freeze quicker, resulting in time, money and energy savings.

- Products wrapped at high temperatures require ventilation to allow heat and moisture to escape and prevent condensation building up.

|

|

Ventilated Stretch Film is available in 500mm x 500m hand rolls. Product code: 55700.

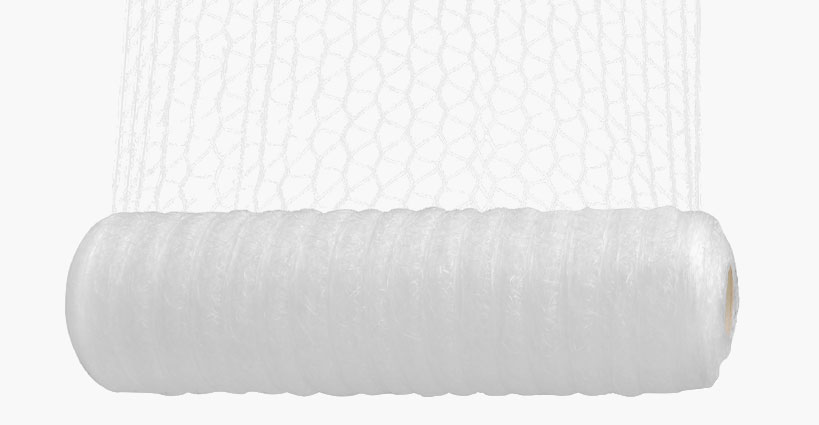

Stretch Pallet Netting

Stretch Pallet Netting is exactly what it sounds like it is: stretchy pallet netting. Ideal for wrapping perishable products which require good air circulation. Stretch Pallet Netting is strong and flexible and prevents the build up of condensation. It’s also handy for wrapping irregularly shaped or incomplete loads. Netting is lightweight and reduces the volume of packaging to be disposed of by up to 45% compared to stretch film.

|

|

Stretch Pallet Netting is available in 500mm x 1000m hand rolls. Product code: 94051.

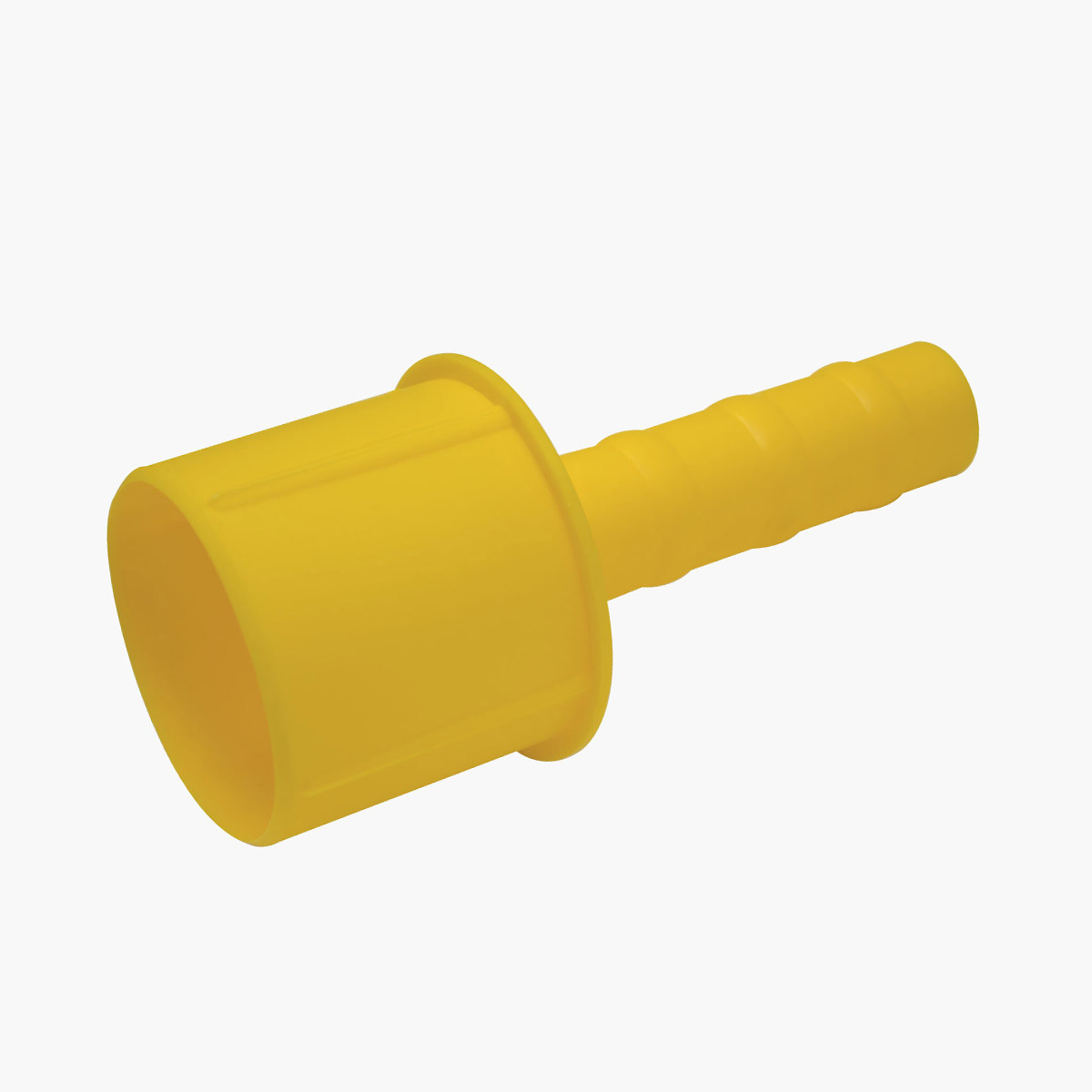

ACCESSORIES AND OTHER USEFUL PRODUCTS

|

All Wrapex® hand films are suitable for use with our Stretch Wrap Hand Dispensers. These heavy-duty dispensers are designed to reduce strain on the operators hands and back, and tension is easily adjusted on the dispenser. Product code: 58002. |

|

Wrapex® premium Bundling Film Dispensers are suitable for use with our bundling film. Product code: 58010. |

|

|

Buying a pallet wrapping machine may seem like a luxury purchase, however over time, a pallet wrapping machine will pay for itself through savings in labour, time and reductions in cost of stretch film. Highgate offer a wide variety of Pallet Wrapping Machines that are suitable for use with all Wrapex® machine stretch films. Click HERE to view our range of pallet wrapping machines, or contact us for advice on which machine would best suit your business.

|

|||

|

|

|

|

If your pallets are being transported in an open tray truck, you need to consider the environmental factors that could damage the pallet load. A securely and consistently wrapped pallet with a plastic top sheet over will protect your load against dust and water damage.

|

Pallet Top Protectors are available in the following options: |

Cardboard Pallet Protector Pads protect your products from any nails, splinters, dirt or slight moisture on the base of the pallet. You’ll avoid damage by keeping your products clean and sealed.

|

Cardboard Pallet Protector Pads are available in 1160mm x 1160mm sheets. Product code: 06001. |

|